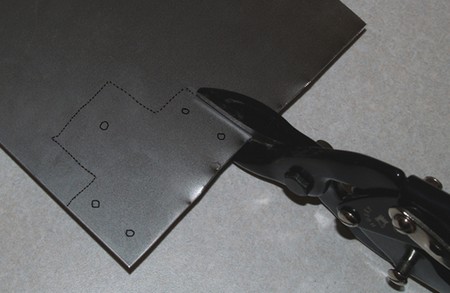

Sheet metal can be cut to size by using snips or shears rather as scissors are used to cut paper. Snips usually have plain handles – like pliers – so that you can grip them lightly and cut thick material. If you need more materials for your project, consider contacting stainless steel fabricators for sheet metal fabrication services.

A few snips are made with bow handles similar to those on scissors. Most snips have their stops behind the blades rather than at the end of the handles which prevents tummy ‘nipping”. Some are spring-loaded and some have double-jointed, high-leverage handles. All snips, however, are intended for trimming small sheets of metal rather than cutting up large ones.

There are three main types of blade: straight, curved and universal. Straight blades are quite deep but thin and can be used for cutting straight lines or trimming round the outside of a piece of sheet. Curved blades are also deep and thin and can be used to cut inside curves. Universal blades are a compromise. They are straight but much less deep than the others and this means that they can be used to cut inside curves as well as straight lines and outside curves.

The handles of snips may be in line with the blades or cranked out of line. Snips with cranked handles and universal blades can be used to cut inside curves in large sheets, but they can cut in one direction only – according to which way they are cranked; left-handed snips have to be used clockwise, right-handed snips anti-clockwise.

Snips are available in a variety of sizes from about 150mm to 350mm in overall length. Their length gives a rough guide to the leverage you can obtain with them when cutting – the larger snips are for cutting thick or tough sheet. For general use, a 250mm pair of snips with plain handles in line and with a universal blade should suffice.

When using snips, try to:

- cut as near to the pivot as possible. This gives better leverage and reduces the risk of forcing the blades apart

- avoid closing the blades completely. If you do, the snips will leave a nick in the edge of the sheet every time

- keep the pivot of the snips oiled and tight rivets can be tightened by using a hammer, carefully.

The cut edge left by snips is often sharp and jagged and should be smoothed with a file.