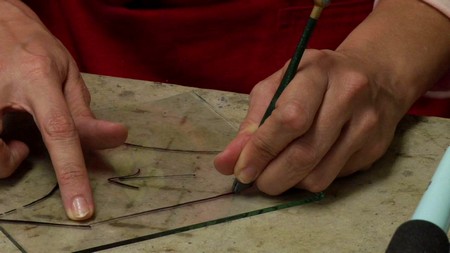

Cutting holes

If you want to make a large circle in a pane of glass to take an extractor fan, perhaps – you will need a different sort of glass cutter: a beam compass (or circle) cutter. This consists of a pivot with a rubber suction pad, an adjustable beam and a cutter on the end of the beam.

As with straight line cutting, the first thing to do is to score the glass, having first set the cutter to the radius you want. The pivot with its sucker should be supported with one hand while the other applies gentle pressure to make an even continuous score. Now score a second circle inside the first and make straight line scores with this circle going right to the edge but not beyond until there is a good crosshatched pattern Make a few radial scores to the outer circle. Tap the glass lightly on the back, starting at the centre of the circle, until some of the glass falls out. Go on tapping – or use a breaker rack to remove the remaining pieces. Finally, smooth the cut edge with line glass paper wrapped around something circular a screwdriver handle, say.

When cutting a hole near the edge of a pane of glass, it is better to cut the hole first and cut the pane to size afterwards.

Circular glass cutters can also be used for cutting discs of glass. To do this, tangential lines are scored to the scored circle and the pieces broken off as with straight line cutting. The finished disc will need a considerable amount of smoothing to get it perfectly round.

Drilling holes

To drill holes in glass, a special glass bit should be used – these are often shaped like a spear. Masonry drills should not be used: they are likely to shatter the glass.

Once the position of the hole has been decided, put a ring of putty or plasticine around it to form a well and fill this with a small amount of lubricant water, paraffin or white spirit. The glass should be well supported on the back with several layers of newspaper.

The main problem is starting the hole in exactly the right place as the drill bit will tend to skid across the glass. Use a slow speed to start the hole, preferably with the drill mounted in a drill stand. Light pressure should be maintained and the speed kept down to prevent the drill bit overheating. Reduce the pressure as the bit comes to the end of the hole.

When drilling mirrors, start the hole from the back – to make a clean cut through the silvering – and once the drill point makes a pinhole on the other side, turn the mirror over and finish off from the front.

When drilling holes in bottles, fill the bottle with sand and rest it in a bed of sand to hold it in position. Slop drilling from time to time to lubricate the drill bit or the hole.

If all this sounds like too much bother, get a glass merchant to drill the holes for you. Unless you are drilling a large number of holes, this will not be very expensive.