Adhesives provide a useful way of making permanent joints between metals. They are particularly suitable for:

- Joining two different metals which are considerably different in thickness;

- Joining thin and relatively weak metals which would be damaged by other joining techniques;

- Places where a smooth finished joint is necessary;

- Joining awkwardly shaped pieces of metal.

When using an adhesive for joining metals, make sure that the surfaces are clean and free from dirt and grease. Avoid using adhesives when the joint will be under constant loads.

Contact adhesives

These adhesives should not be used where a strong joint is essential. To make the bond, apply the adhesive to both surfaces and leave them to become tacky. Then hold the two surfaces together they should bond immediately.

Cyanoacrylate adhesives

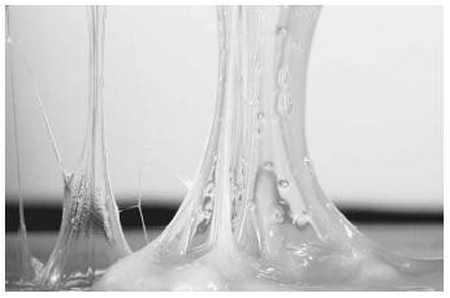

These adhesives are based on cyanoacrylate esters and produce very strong bonds. They are very easy to use simply spread a very small amount of glue on one component and hold the other one in contact with it for approximately 10 seconds. Do not use too much glue. Cyanoacrylales harden by reacting with the thin film of water present on most things, and if there is too much glue (or too much water) present the result will be a weak joint. Once the parts are pressed together they cannot be repositioned (so there is no need to clamp things) and the joint quickly reaches full strength.

Use cyanoacrylatcs with care they form strong bonds with human skin, so you should avoid getting any on your fingers or in your eyes and should always store them well away from children. If you do have an accident – bond your fingers together, say plunge the affected parts in hot soapy water as quickly as possible and try to peel the joined surfaces apart as the glue softens. You can use a teaspoon handle as a lever. Do not try to pull the surfaces apart. You can wear polythene gloves when using cyanoacrylatcs but do not wear rubber ones.

Epoxy resins

These adhesives produce strong joints but need a long setting time – often around 24 hours. They usually come in two parts a resin and a hardener which have to be mixed together immediately before they are applied. A chemical reaction then takes place which produces heat and cures the joint. The time taken to cure the joint can be shortened by warming it.

Epoxy resins tend to be brittle when set and should not be used for joints which are liable to be flexed in use. Two-part acrylic adhesives form strong heat-resistant joints on metal, though they do not have the same gap-filling properties as epoxy resins. To use this type of adhesive, one part is spread on one component and the second part on the other component and the two components held together for one to three minutes until the adhesive has set. The adhesive will be strong a few minutes later, but full strength will not be reached for 24 hours.